An algorithm to improve processing of lentils

Infrared and microwave treatments for milled lentils are being optimized for the Saskatchewan market

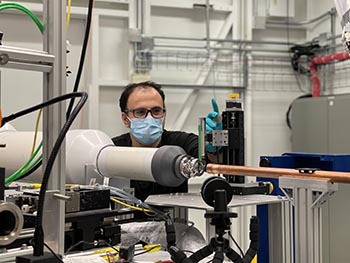

By Brian OwensVenkatesh Meda, Tahereh Najib, Mehdi Heydari on CLS Mezzanine

Lentils are a major food crop produced in Saskatchewan, either eaten alone, ground into flour, or increasingly as part of the growing market for plant-based meat alternatives. The choice of an appropriate thermal pre-treatment and processing of lentil seeds into flour can enhance the consumption of lentils by improving their nutritional profile and providing new ingredients with various functional properties to be used in food applications.

That can be time and energy-intensive, so Venkatesh Meda, a Professor of Chemical and Biological engineering at the University of Saskatchewan, and his research team has been developing methods that effectively use microwaves and infrared energy to speed up the modification process and make it more selective. Altering starch and protein structure during the modification process of lentil seeds can bring about the desirable changes in the functional and nutritional properties of its flour.

“Infrared and microwave energy together can enhance the nutritional and functional properties of the seeds and the flour milled after the treatment,” he says.

Microwave assisted processing has been used in the agri-food industry in other parts of the world, but not in Saskatchewan. So, Meda, along with his PhD students Mehdi Heydari and Tahereh Najib, has developed an algorithm (model) that describes what happens to lentils as they are microwave-processed, with the goal of helping the local industry adopt the process.

“We are looking at how we can optimize the process to make recommendations for a pilot plant or industrial-scale applications,” Meda says.

The algorithm considers variables such as the lentils’ water content, temperature, the power of the microwave, and how these factors influence functional and structural changes in starches and proteins.

But the amount of energy that gets absorbed, and what it does to the lentils, is not easily measurable using common laboratory tools. For that the team turned to the Canadian Light Source (CLS) at the University of Saskatchewan.

The CLS’s mid-infrared beamline allowed them to see how variations in the time and power of microwave processing changed the structure of the starch and proteins in various preparations of lentils, from full seeds to milled flour. This is important because these changes to starch and protein can affect how stable the lentils or ingredients are on the shelf long-term, and what kinds of foods they can be processed into. By including these variables in the algorithm, lentil processors will be able to optimize the power levels and cooking times to get the result they want as quickly and efficiently as possible.

Meda hopes that his algorithm can help Saskatchewan’s lentil producers adopt microwave- infrared processing to save time and energy during processing. More efficient and targeted processing could encourage increased use of the locally-grown crop in applications like plant-based protein, with benefits for both the environment and the economy.

“The more of these that are grown by our farmers, the more added nitrogen fixation in the soil. It indirectly contributes to the circular economy as a whole because of the environmental footprint and benefits,” he says.

Heydari, Mohamad Mehdi, Tahereh Najib, Oon-Doo Baik, Kaiyang Tu, and Venkatesh Meda. "Loss factor and moisture diffusivity property estimation of lentil crop during microwave processing." Current research in food science (2021). https://doi.org/10.1016/j.crfs.2021.12.008

Media Relations:

Victoria Martinez

Communications Coordinator

Canadian Light Source

306-657-3771

Victoria.martinez@lightsource.ca