New Linear Accelerator

Investment will ensure continued world-leading discovery, innovation

The Canadian Light Source (CLS) at the University of Saskatchewan is replacing its linear accelerator (linac), the device that speeds up electrons to produce a beam of light researchers use to study materials at a molecular or cellular level. This critical replacement will ensure the CLS continues to deliver high-quality, stable and reliable light to the over 1,000 scientists from across Canada and around the world who use the CLS each year for research related to health, agriculture, environment and advanced materials.

In May 2024, we began a project to replace our linac with a new unit that will improve the efficiency and reliability of the light beam. For the latest updates, check back on this page or follow us @canlightsource on social media for #newlinac posts.

Current Beamline Status

The latest news...

This project began with the removal of the original LINAC, and installation of a new system designed to enhance reliability and performance. The installation was completed successfully by CLS, and over the following months, our team, in collaboration with the vendor and international partners, carried out extensive conditioning and testing to ensure optimal operation. While we encountered challenges, including the need to address a significant issue with one of the accelerator sections, these were resolved through innovative approaches by the CLS team and strong vendor support.

By October 9, 2025, we successfully restored beam in top-up to the beamlines to start to welcome early user science, and as of early December, we have maintained over 1,000 hours of beamtime with exceptional reliability. More than 400 early users from 29 institutions have already resumed their research, and we are proud to report that most beamlines are now operating at full performance. Our October call for users to reapply for beamtime met with an enthusiastic response and we look forward to welcoming all of you as our regular beamtime cycle resumes in January 2026.

Looking ahead, this upgrade positions CLS to deliver even greater scientific impact. The new LINAC enhances beam stability and reliability. Researchers will benefit from improved top-up operations and consistent beam quality, opening opportunities for cutting-edge work in health, agriculture, environmental science, and advanced materials. These improvements ensure that CLS remains a world-class facility supporting discoveries that address global challenges.

Beyond the LINAC project, this has been a period of significant progress across the facility. Expert reviews of all beamlines were completed and limited offline operations continued, along with extensive support for users through data analysis and outreach. We upgraded instruments, expanded AI and high-performance computing capabilities, delivered training programs, and strengthened international engagement. Additionally, we developed the Major Research Facilities scenarios for submission to the Canada Foundation for Innovation in September, ensuring CLS aligns with emerging national research priorities.

This accomplishment reflects not only the dedication of our technical teams but also the resilience and commitment of our user community. We recognize the impact that delays have had on your research programs and deeply appreciate the flexibility and trust you have shown during this period. With the beam now stable and shining brightly, we look forward to supporting your scientific endeavors with renewed energy and confidence.

Thank you for your continued partnership and for being an integral part of the CLS community. Together, we are entering a new era of discovery.

Bill Matiko, Chief Executive Officer

Ingrid Pickering, Chief Science Officer

Kevin Wyatt, Interim Machine Director

December 3, 2025: Since early October we have been able to deliver 220mA beam in top-up mode to all beamlines, with over 1,000 hours of beamtime at 96% beam availability, for testing, as well as for nearly 400 early users from 25 Canadian institutions.

As we continue to monitor the performance and reliability of the linear accelerator (linac), a new accelerating section (ACC4) has arrived and will undergo onsite testing soon, in preparation for installation should the replacement of an operating accelerating structure become necessary.

We look forward to welcoming all users back in the new year.

October 24, 2025: Thank you to all who joined our User Community Forum last Thursday. This was an exciting time to hear about the science that is thriving in our community and to discuss the LINAC project and plans for the future. For those who were unable to attend, we are pleased to share an important update on the status of the LINAC and our return to operations.

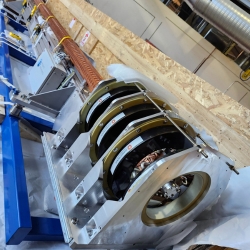

Our previous update shared news of a significant setback involving one of our three accelerator sections (ACC2), and our plans to replace it with a new section (ACC4). While we await the arrival of ACC4, our accelerator team has been working to recondition ACC2 and reconfigure the booster ring to accept beam using modified settings. Their innovative approach involves injecting at a lower energy from the LINAC, which allows us to provide beam for users while continuing to condition the machine. These efforts have seen encouraging success, and in a modified configuration, we are now able to operate, delivering 220mA top-up beam!

These results are so promising that our original plan to replace ACC2 expeditiously has been revised. On October 10, we convened our expert Machine Advisory Committee (MAC) to assess the status of the LINAC and provide guidance on the best path forward. Following a thorough review, the MAC recommended that CLS continue operating with ACC2 unless an exchange becomes necessary. CLS Executive has endorsed this recommendation.

Already, several beamlines have begun supporting local and mail-in users to verify performance following the long shutdown. Provided the machine continues to run reliably, and as beamlines return to operations one by one, we anticipate welcoming early users throughout the remainder of the calendar year, with full user operations expected to resume in January.

Expressions of Interest submitted through the User Portal in the form of Beamtime Requests or new proposals will be accepted until October 29, 2025 at 12pm (noon) CST for beamtime in the first half of 2026.

We will continue to monitor ACC2 closely and are prepared to adjust our plans should a replacement become necessary. In the meantime, we are thrilled to see users return to our experimental floor and look forward to supporting your science in the months and years ahead.

For the latest updates, please visit our website and follow our social media channels. You can also view the live status of the storage ring on our Machine Status Display, which reflects real-time activity.

Thank you again for your continued patience, support, and enthusiasm. Your research drives everything we do, and we are so grateful to have you back.

| Bill Matiko Chief Executive Officer Canadian Light Source |

Ingrid Pickering Chief Science Officer Canadian Light Source |

Kevin Wyatt Interim Machine Director Canadian Light Source |

September 5, 2025: We are writing to share an important update regarding the LINAC and our operational plans for the remainder of 2025. Since our last message on August 6, we encountered a major setback: one of three accelerator sections in the LINAC is showing signs of failure and must be replaced. In light of this, we deeply regret that we do not anticipate reliable beam for user operations until early 2026.

The failing section is the same one that raised significant concern earlier this year, at which time our vendor began fabricating a replacement. Given the progress over the early summer, it appeared we would be able to operate for some time before implementing a long-term solution. However, it is now clear that the replacement must be completed as soon as possible to ensure reliable operations. Our vendor is accelerating the remaining work, and we expect delivery of the new section this fall.

In addition, our planned fall shutdown activities have been significantly revised. The scheduled University of Saskatchewan power outage—previously a key driver of our timeline—has been cancelled. After completing essential maintenance and safety certification, we will use the remaining time for ongoing RF conditioning of the problematic LINAC section. If successful, we will attempt to put beam in the Storage Ring for beamline testing after the planned shutdown ends on October 7. Any beam delivered in this configuration would be expected to be intermittent with limited reliability.

Once the replacement LINAC section and related components arrive and pass on-site inspection, installation will begin immediately. Thanks to the progress made over the summer, our timeline to beam following bakeout and reconditioning is significantly shortened, as many of the challenges with achieving top-up have already been addressed. A revised set of milestones is now available on our website. Provided the completion and delivery of the replacement section remain on track, we are hopeful that beam delivery for users will resume in early 2026.

To help us plan for our return to operations, we will issue a call for expressions of interest later this fall to determine which users disrupted by the outage still require beamtime for their projects. You can expect a detailed update by early October.

We also want to support your ongoing research and funding efforts. A letter is now available on our website for inclusion in grant applications, explaining the nature of the delays and affirming that they are due to facility issues outside of user control. We encourage you to reference this letter as needed: https://www.lightsource.ca/documents/operations-update-2025.pdf.

We recognize how essential access to the facility is for your research, and we want to assure you that your work continues to be our top priority. Your science drives everything we do. We’re sincerely grateful for your patience and understanding throughout this extended outage, and we remain fully committed to restoring full operations as swiftly and safely as possible.

We encourage you to visit our website and follow our social media channels for the latest updates. You can also view the live status of the storage ring on our Machine Status Display, which reflects real-time commissioning activity.

Thank you again for your continued support—we look forward to welcoming you back soon.

| Bill Matiko Chief Executive Officer Canadian Light Source |

Ingrid Pickering Chief Science Officer Canadian Light Source |

Kevin Wyatt Interim Machine Director Canadian Light Source |

August 6, 2025: We are pleased to share that on July 25, we observed the first beam in the storage ring from our new linac—a major milestone in our commissioning journey. Since then, we have made great strides, storing 220mA in the storage ring and demonstrating the ability to perform top-up operations.

While our original timeline projected beam delivery to beamlines in decay mode by late November 2025, we are now cautiously optimistic that we could see our initial return to user operations as early as the beginning of November. Much work remains to ensure stable operations for user science. This includes ongoing conditioning and diagnostics of the linac to improve beam stability and gain a better understanding of its characteristics, with the goal of enhancing beam injection into the booster ring and achieving reliable acceleration to 2.9 GeV. Further tuning of machine systems is needed to ensure efficient transport of the electron beam from the booster to the storage ring, and effective capture in the storage ring. Extensive beamline testing is also required to ensure all systems are performing reliably and ready for user operations.

We understand how critical access to the facility is for your research. Your work is not just important to us—it is the driving force behind everything we do. We are deeply grateful for your continued patience and support throughout this extended outage, and we remain committed to restoring full operations as quickly and safely as possible.

| Bill Matiko Chief Executive Officer Canadian Light Source |

Ingrid Pickering Chief Science Officer Canadian Light Source |

Kevin Wyatt Interim Machine Director Canadian Light Source |

June 12, 2025: We are encouraged to share that a path towards resuming normal operations has been established. Full details of the milestone steps are outlined above. While there is still significant uncertainty around the exact timing of each stage, current projections suggest that low-quality, unreliable beam may be delivered to the storage ring during the summer months, though it will not be suitable for scientific use. Reliable beam is tentatively anticipated by late November 2025, pending continued success in commissioning and system validation. As the technical team works through this complex process, we expect to encounter and resolve minor technical challenges, supported by a strong and productive collaboration with our vendors. With the completion of each milestone, our confidence in predicting the date of our return to operations will increase; however, at this stage, there is not sufficient certainty to begin rescheduling any beamtime.

We recognize how disruptive this extended outage has been and are extremely sorry for the impact it has had on your research, your students, your collaborators, and your plans. Both the Board and executive leadership share your concerns and are committed to ensuring that the resources and institutional support necessary to complete this work are in place. The entire CLS team remains fully committed to restoring operations as safely and swiftly as possible. We are incredibly grateful for your patience, understanding, and continued support during this time. We look forward with real excitement to welcoming users back to the CLS later this year and supporting the important work about which we are all so passionate.

To help support users navigating funding challenges resulting from these delays, we intend to prepare an open letter outlining the broader LINAC-related disruption at CLS. Once we have greater clarity on the full duration and impact of the outage, this letter will be publicly posted on our website for users to reference or include in grant applications or related correspondence to help contextualize the interruption in research access that may have affected their work, independent of any project-specific factors. If you would benefit from this type of supporting documentation prior to its public release, please contact the CLS User Services Office for assistance.

We will continue to provide detailed updates as we move through each stage of the process, or in early July at the latest. In the meantime, we encourage you to visit our website and follow our social media channels for the latest information.

| Bill Matiko Chief Executive Officer Canadian Light Source |

Ingrid Pickering Chief Science Officer Canadian Light Source |

Martha Crago Chair CLS Board of Directors |

Baljit Singh Vice-President Research University of Saskatchewan |

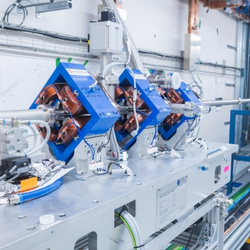

April 11, 2025: We have made meaningful progress in commissioning our new linear accelerator (linac). Our team of staff from CLS and RI Research Instruments GmbH (RI), our vendor, have been consulting with experts from other facilities, including an on-site visit from a MAX IV linac expert, to learn from their experience and approaches in conditioning a linac similar to ours. Following expert advice, we completed a bake-out of one linac section, which improved vacuum conditions and overall system performance. We have also modified our radiofrequency (RF) conditioning strategy to adopt a more gradual process. This slower approach is already yielding positive results.

Based on these encouraging developments, we now plan to bake out all three linac sections before continuing with our revised RF conditioning strategy, with the potential for some beam delivery to the storage ring as early as July. While this is an important step in restoring user operations, any storage ring beam at this stage would likely be unstable, which is not suitable for research use. Therefore, we remain unable to provide a definitive schedule for our return to normal operations and will provide a more concrete timeline as our technical work advances. We are enormously grateful for your continued patience and understanding as we work to restore operations.

March 27, 2025: The process of baking out accelerator section 3 began on March 19, 2025. This heating process will take about a week and should be complete soon. After that, all the diagnostic tools will be moved to section 3, and the next step - RF conditioning - should start on March 28, 2025. If the bakeout of section 3 provides improvement to the RF conditioning, we will do the same for the other two structures. otherwise we will focus on delivering user beam with current conditions.

Experts from MAX IV, Sweden’s national synchrotron, will visit CLS starting on March 31, 2025 for a week, to support our ongoing efforts. Max IV's new linac is very similar to CLS’s and their experience bringing their system online will be invaluable as we work towards stable user beam.

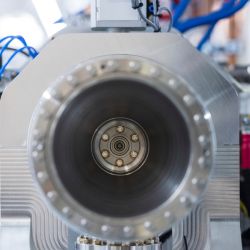

In parallel to the heating up of section 3, we resumed RF conditioning of section 1 on March 19, 2025. Section 1 is currently at around 26MW at 0.2 microseconds, and our goal is to reach 30MW at 4.5 microseconds. We have collected data from microphones and directional couplers at each end of sections 1 and 3 to find out where the issues are. This data, which we’re sharing with the LINAC vendor, Research Instruments (RI), and our colleagues from other facilities – including CERN, MAX IV, SLAC, and Elettra - shows that there might be arcing near the section input couplers.

We are grateful for everyone’s patience as we put all our efforts towards bringing beam back.

March 4, 2025: A joint message from CLS and RI: Last year the Canadian Light Source (CLS) contracted RI Research Instruments GmbH (RI) to design, build, install, and commission a new linear accelerator (LINAC). While installation of CLS’s new LINAC was completed successfully and on time in August 2024, problems encountered during commissioning have prevented the CLS from resuming regular operations. Staff from RI and the CLS are working around the clock – onsite and remotely – to determine the cause of the setback and to restore beam to CLS users as soon as possible.

Together, RI and CLS have been carrying out a multifaceted investigation of the problem, including a thorough inspection and qualification of all the LINAC RF components, as well as new RF diagnostics and RF pieces. The new RF components have either been loaned or purchased by RI, or fabricated by RI or CLS, and have been qualified onsite at the facility. Because of the time required to carry out this troubleshooting, CLS must regrettably cancel a large portion of scheduled user time in 2025.

The unexpected problems encountered in commissioning the RI LINAC – a product known for its robustness and successful operation in labs around the world – have prompted our two organizations to seek external expertise from other accelerator laboratories. We are soliciting input on the design, quality assurance processes, and the commissioning methodology. In anticipation of the potential need to replace accelerating structures and to minimize the schedule impact, RI is already manufacturing structures and procuring the copper needed if more structures are required.

Our two organizations are aligned in our shared goals to have CLS resume user operations as soon as possible and to provide the LINAC to original specification.

Bill Matiko

Chief Executive Officer

CLS

Michael Pekeler and Christian Piel

Managing Partners

RI Research Instruments GmbH

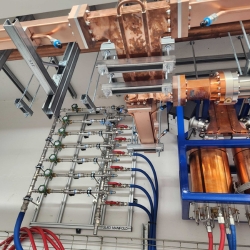

June 6, 2024: With the old linac equipment removed from our basement, our health and safety staff needed to scan these pieces for radiation before they could be recycled or donated. They have now checked over 175 items! Next, we cleaned the linac hallways and started giving them a fresh coat of paint. Our staff also fully dismantled our modulator room. Klystrons, modulators, and other infrastructure were removed, making way for the mechanical and electrical service installation that is now ongoing. We have new modulators and klystrons waiting on our experimental floor. This equipment will provide the radiofrequency energy that is used to accelerate electrons through our linac before they produce synchrotron light for research.

May 30, 2024: The CLS has been dark for a short time, but there has already been a significant amount of progress thanks to our hard-working team. Once our operators turned off the machine, we soon started to dismantle the electron source and linear accelerator in our basement. Our staff have already removed the power supply tank, accelerating sections, and other assorted infrastructure. About 90% of the removed equipment will be recycled and the remaining 10% will be donated to universities or museums. The appearance of our basement has already changed dramatically. The linac hallways that are usually filled with specialized equipment are looking quite empty. While it may seem that this project has just begun, years of planning have led us to this point to help ensure the transition goes as quickly and smoothly as possible. Our team of engineers, technicians, physicists, and many others carefully prepared for when the key was turned for the final time and the six months of work that would follow. Installing a new linac will ensure the CLS provides high-quality, reliable synchrotron light for innovative research for years to come.

May 27, 2024: Starting today, the Canadian Light Source (CLS) at the University of Saskatchewan will begin work to replace its linear accelerator (linac) - the system that speeds up electrons to produce the ultrabright light researchers use to study materials at the molecular or cellular level. The new linac will replace aging infrastructure from the Saskatchewan Accelerator Laboratory that dates back to the 1960s and the early days of the CLS, and will enhance the facility’s efficiency and reliability. Over the next six months, staff will remove the old linac, its electron source and associated operating systems and refurbish the underground tunnel in which it is located. A new linac with a shorter and more modern design will then be installed, including accelerating devices, electromagnets, high-power radiofrequency transmitters, computer control system and ancillary systems, under the direction and supervision of the vendor, Research Instruments (Germany), who designed and built the system. Read more