Canadian researchers extend the life of rechargeable batteries

Carbon coating that extends lithium ion battery capacity by 50% could pave the way for next-generation batteries in electric vehicles.

By Victoria MartinezAn electric car charging at a charge station.

Researchers from Western University, using the Canadian Light Source (CLS) at the University of Saskatchewan, found that adding a carbon-based layer to lithium-ion rechargeable batteries extends their life up to 50%.

The finding, recently published in the journal ACS Applied Materials and Interfaces, tackles a problem many Canadians will be familiar with: rechargeable batteries gradually hold less charge over time.

“We added a thin layer of carbon coating to the aluminum foil that conducts electric current in rechargeable batteries,” said lead researcher Dr. Xia Li of Western University. “It was a small change, but we found the carbon coating protected the aluminum foil from corrosion of electrolyte in both high voltage and high energy environments – boosting the battery capacities up to 50% more than batteries without the carbon coating.”

Aluminum foil is commonly used on the cathode as a current collector where electricity leaves the battery of rechargeable lithium ion batteries. This foil has high electronic conductivity and is lightweight and low cost, but the new generation of batteries brings new challenges to the current collectors, which will need even more chemical stability to protect against the corrosion of electrolyte in the cathode. This will help to maintain long battery life cycles.

Rather than find an entirely new material for cathodes, the Western team tested a super-thin coating produced by 3M Canada, called graphene.

Li sees electric vehicles as a key application for better battery technologies, and is excited about the green energy sources batteries can support in general.

“We are very interested in using batteries to develop a new clean energy society,” said Li. “Oil is not a good long-term choice for humans and when we convert to green energy sources, we need clean secondary energy storage devices.”

Because of its conductivity, flexibility, and availability, this thin carbon coating could become a key tool for developing battery technologies for a greener future.

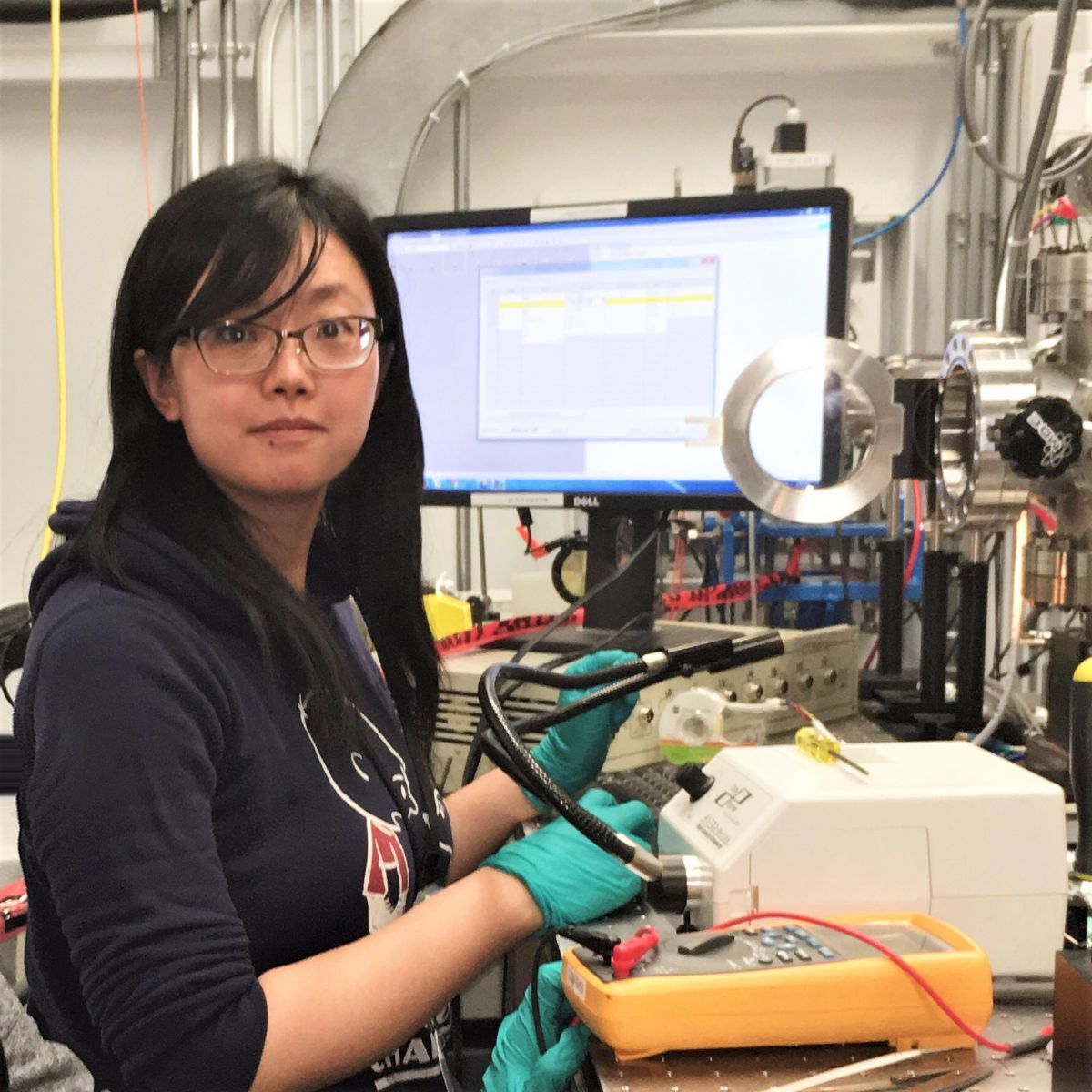

Li is part of Prof. Xueliang Andy Sun’s Advanced Materials for Clean Energy research team at Western University. The research team collaborated with 3M Canada researchers, which provided the carbon coating, and the CLS, which provided the synchrotron light required to test the coating.

About the study

For years, Prof. Sun’s group has harnessed the power of synchrotron light at the CLS to help develop more advanced batteries.

“Without synchrotron radiation, it's very hard for us to understand the chemistry and electrochemistry reactions of batteries. But synchrotron techniques can tell us the what kind of reactions happen and offer very important guidance for the design of future battery materials,” said Sun.

The team used extremely bright X-rays at the CLS to identify what chemical changes occur on delicate battery surfaces while they are operating. Their analysis showed that the coating is effective in both high-voltage and high-energy environments, which would be important for applications like electric vehicles.

Li, Xia, Sixu Deng, Mohammad Norouzi Banis, Kieran Doyle-Davis, Dongxing Zhang, Tengyuan Zhang, Jun Yang et al. "Suppressing corrosion of aluminum foils via highly conductive graphene-like carbon coating in high-performance lithium-based batteries." ACS applied materials & interfaces 11, no. 36 (2019): 32826-32832. DOI: 10.1021/acsami.9b06442.

For more information, contact:

Jeff Renaud

Senior Media Relations

Western University, London, ON

519-520-7281

jrenaud9@uwo.ca

Victoria Schramm

Communications Coordinator

Canadian Light Source, Saskatoon, SK

306-657-3516

victoria.schramm@lightsource.ca